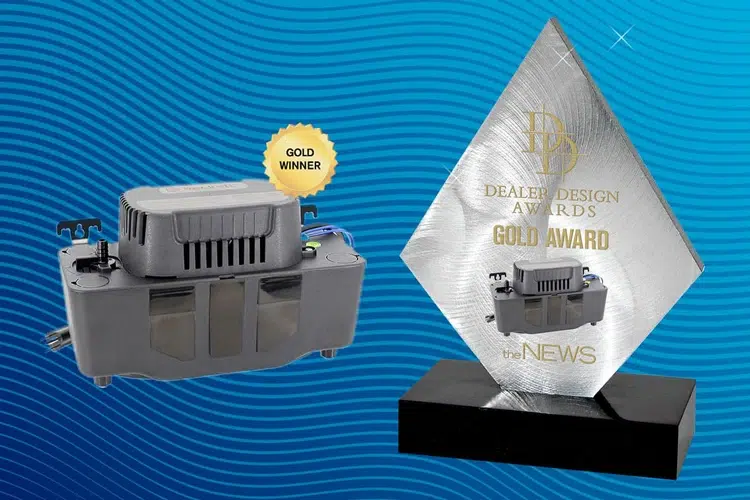

ACHR News Design Award

Beckett's BK221UL Condensate Pump has been recognized for excellence in product design in the 2023 Dealer Design Awards Program.

Pumps You Can Trust

Since 1948, we have built our name in pumps. Today, we offer pumps for demanding applications including HVAC, Refrigeration and many OEM applications.

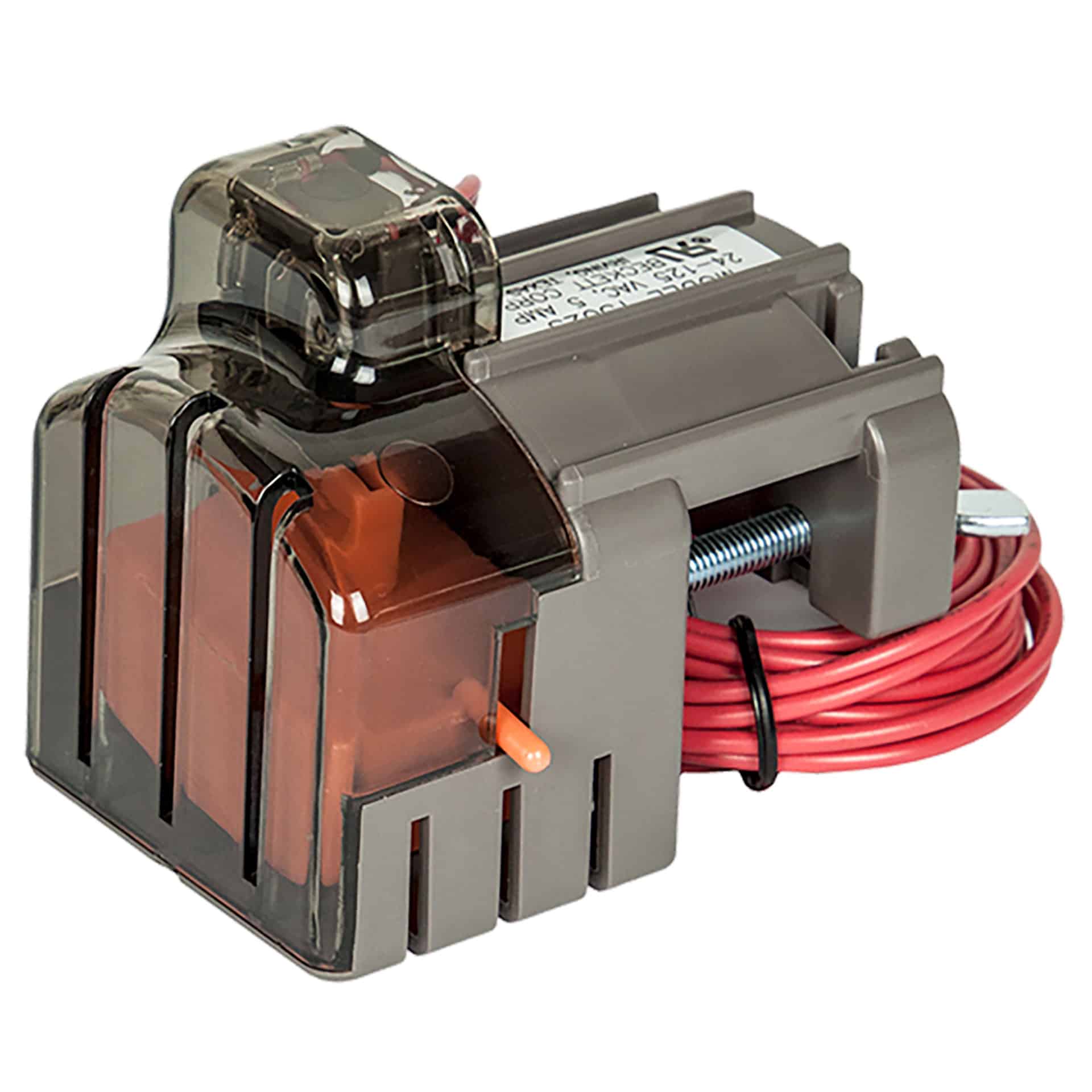

Condensate Management

As the choice of HVAC professionals, Beckett offers a full range of condensate pumps for almost any application (small, medium, large, mini split, high-temp, plenum rated and more).

OEM & Custom Pumps

We work with OEMs producing specialty equipment for HVAC/R, computer room A/C, refrigeration, ice machines, evaporative cooling, tile saws, parts washers, oil skimmers and more.

Ice Machines

Leading ice machine OEMs have chosen Beckett for their pump solutions. Our experienced OEM team can fast track your project to optimize the design, materials, quality and costs.

Our Product Catalog

Beckett Product Categories

Best Resources for Customers

Our Resources

About Beckett Corporation

Dependable Pump Solutions

Since 1948, Beckett has been a recognized leader in designing innovative and reliable pumps and accessories for the HVAC, OEM markets and a range of Submersible Pumps. While manufacturing pumps remains the core of our business, over the years we have transformed to reach a broader range of customers.

Beckett Products

High Quality Pumps and Accessories

Customer Testimonials

What Customers Say About Our Products

HVAC Contractor

Service Manager - Southeastern U.S.

"Beckett is without a doubt our go-to condensate pump. The BK pumps are packed with features that make installation super easy, plus they're very reliable and priced at a good value for our customers."

OEM Product Manager

OEM Using Beckett Condensate Pumps

"Beckett's speed and flexibility made them the ideal supplier to partner with. We needed proven performance, cost assurances, and speed to market."

Jack

CB151LSUL Medium Condensate Pump w/o Safety Switch, 17 Ft Shutoff (1/50 HP, 115V)

"Found that the condensate pump on my heater was bad. It is in a vacation house, so not fixing it wasn't an option nor was showing up without the right parts. This pump was exactly what I needed. Highly recommend this part."

Homeowner – Condensate Pump

CL201UL Low Profile Condensate Pump, 20 Ft Shutoff

"I use this with my furnace, which is down in the crawl space under the house. It works well, and since this is a pretty harsh environment, I decided to get a spare. Usually gets checked once a year and cleaned as necessary. I was very pleased with the service from SupplyHouse.com"

OEM Engineering Manager

OEM Using Semi-Custom Submersible Pumps

"Beckett’s OEM team was very responsive during the product development process to optimize our design, including materials, costs, testing and overall pump reliability."

OEM Product Engineer

OEM Using Beckett Drain Pumps

"Beckett's wide range of core pump technologies gives us more options for an extremely reliable pump without the added costs of a custom product."

WS – Homeowner

680 GPH Submersible Pond Pump

Michael W – Homeowner

160 GPH Submersible Low Water Auto Shut-Off Fountain Pump

Easy to assemble and placed right into service with no issues. I had a pump burn out after 2 years and replaced it with this pump. It has much better flow and makes the water fill the fountain much more efficiently.

Janet – Homeowner

2100 GPH Submersible Waterfall Pump

"Awesome waterfall pump. The other brands we purchased in the past failed after about 3 months. We’re tired of bringing them in for exchange. We’ll stick with the Beckett 2100 from now on."

Beckett's Email News & Updates

Subscribe to Email Updates

"*" indicates required fields

Beckett Corporation News

Our Latest News

Beckett Corporation Refines Focus, Eliminates Water Gardening Business Unit

Irving, Texas – Beckett Corporation, a trusted leader in pump design and manufacturing since 1948, announced today the...

ACHR News Recognizes Beckett with a 2023 Dealer Design Award

Beckett Corporation has been recognized for excellence in product design in the 2023 Dealer Design Awards Program, sponsored by...

Beckett Corporation Celebrates 75 Years

Beckett Corporation is pleased to announce and celebrate its 75th year in business. Founded in 1948, Beckett has...